Price: call us or send an enquiry

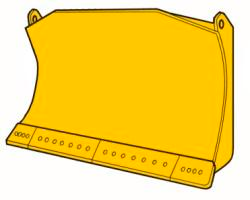

The main operating equipment for any bulldozer is its blade. Its reinforced steel structure with bended profile allows to effectively handle wide range of extremely complicated tasks for road works, construction and other areas.

Land leveling, soil spreading, cleaning of snow or rubbish, assistance fir development of quarries – when this type of jobs is being done, the main load is applied to the dozer blade, that is why it is important that this type of attachment to be manufactured of high quality materials.

To operate on the soil the dozer blade is equipped with wear resistant cutting edges from below and on the sides, and after they are worn out, they are replaced by new ones. Usually the cutting edges mounted in the lower part are double-sided – this means that after the edge is worn out, it can be reversed and you can go on working. More solid side cutting edges are often one-sided, but with the purpose to improve their wear resistance their structure is thickened. To improve service life and resistance to loads blades are made of high quality alloyed steel.

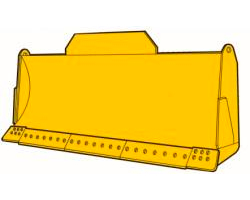

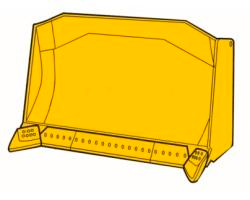

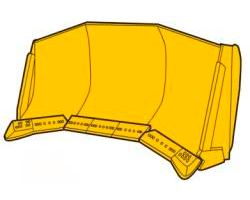

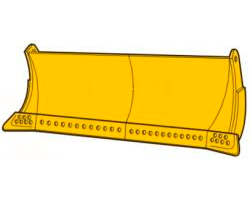

Crawler general-purpose dozers are equipped with multipurpose tilting and straight blades. The latter can be of straight, spherical and semispherical shape, when ends are closed by side “wings”, to avoid loosing soil during transportation. To ensure protection of hydraulic cylinders and heater the blades are equipped with upper grids or plates.

List of products manufactured by “PROFESSIONAL” includes the following types of dozer blades:

The low area of a blade’s front bended plate is equipped with removable cutting edges: two or three central ones (pos. 3; 4) and two end ones (pos. 1; 2), which are shorter. This type of dozer blades complex structure allows immediate exchange of the blade parts and their individual replacement in case they are worn out.

Central blades are normally double sided. Central blades are fastened to the plate by fastening square headed bolts that prevent rotation when fastened with nuts. The bolt’s conical head is put to a counterbored hole of the blade in such a way that it is flushed and does not make any obstacles when soil moves along the blade.

When sharp cutting edge is worn out, it is dismounted from the blade, rotated 1800 and is fastened again. The cutting edge is operated with its second sharp edge until it is worn out too.

Side cutting edges are thickened in order to improve their wear resistance. Side cutting edge is prevented from displacement by two lines of holes where bolts and nuts are fastened. They are single sided, i. e. they have one cutting edge, but they are more solid than the main ones.

to our digest

Our subscribers are the first to know:

Prize

Drawing

Perconal Data

Security

NO

SPAM

By leaving your personal data, you accept the Privacy Policy

Web programming b-m.ru

This site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies. Learn more.

I Accept