Price: call us or send an enquiry

Mining truck bodies production is a fundamentally new direction that the Professional team is actively developing. A large proportion of our clients are mining companies with mining excavators and dump trucks in their fleet. The production of bodies has become an excellent option for import substitution due to the high quality at a low price compared to imported products.

The company produces bodies of the following types and models:

Professional has the necessary equipment for the production of large-volume bodies for large mining equipment and is ready to consider joint production projects with the world's leading manufacturers.

By the middle of 2021, the Professional has mastered the production of the following models of bodies for dump trucks:

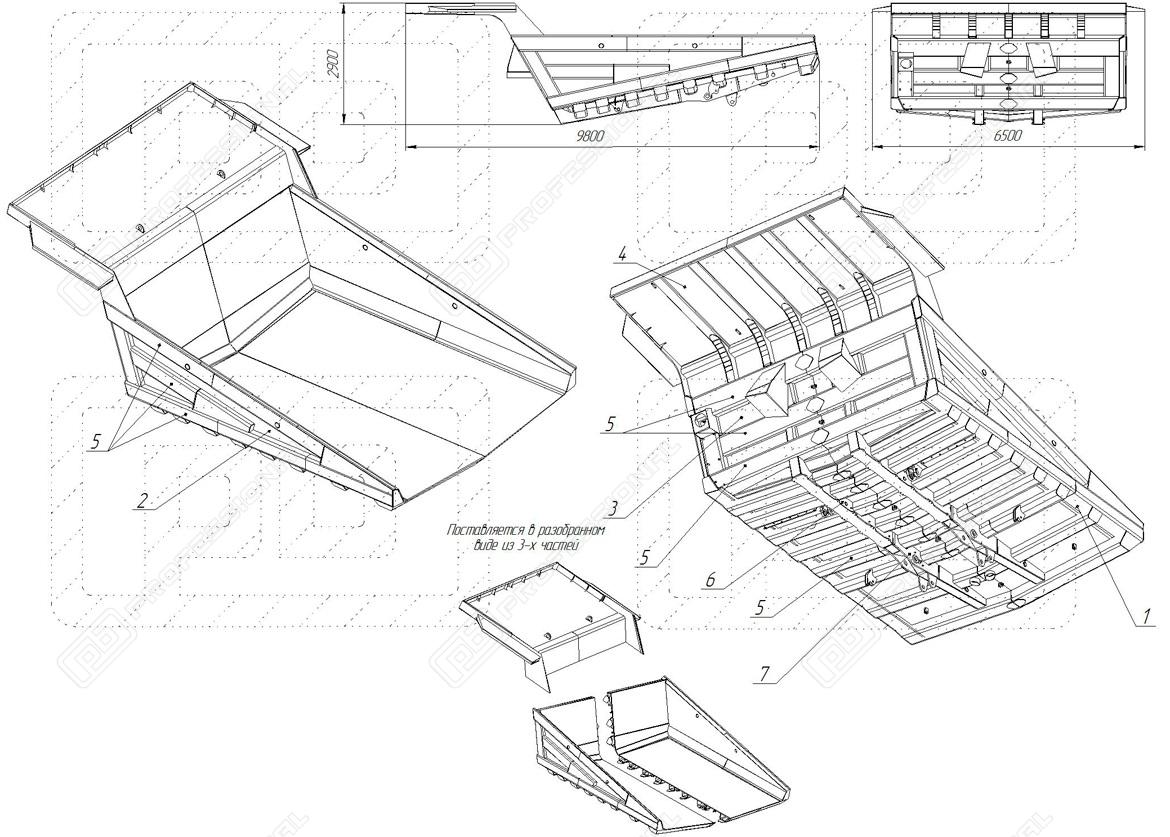

High-strength wear-resistant alloy steel with hardness HB450 of European production is used in the manufacture of the body. At the request of the client, the body of the dump truck can be produced for operation in different climatic conditions and for the transportation of rocks with different densities. The truk body is a welded structure. Mining equipment is distinguished by a high carrying capacity (even the smallest ones have it about 30 tons), and the body capacity, as well as its weight which also plays an important role. The lighter the body (and this is achieved through the use of high quality materials), the higher the payload of the dump truck.

The sequence of the body production is as follows: the plate steel is forwarded to the cutting section, then the workpiece goes to the bending section. The resulting elements of the future body are assembled, welded and transferred to the final stage of production, including the control assembly. Then the body is disassembled again and delivered in this shape to the customer. This stage is due to the fact that a huge body as a bulky cargo cannot be transported either by rail or by public road.

The final stage of assembling of a new body always takes place on site. It is here that the body is reassembled, welded and painted. All these works are carried out by an on-site team of specialists from Professional.

The strategic goal of Professional: the complete satisfaction of the customer's needs in its industry, which cannot be achieved without expanding its range, taking into account all the features of the changing market.

Pattern. Caterpillar 777 body

| 1. Bottom | HB450 | 20 mm |

| 2. Side wall | HB450 | 10 mm |

| 3. Front wall | HB450 | 20 mm |

| 4. Eyebrow | HB450 | 12 mm |

| 5. Beam | S690QL | 10 mm |

| 6. Mounting lug | S690QL | 12 mm |

| 7. Mounting lug | S690QL | 20 mm |

| 8. Liner | HB450 | 12 mm |

| 9. Liner | HB450 | 10 mm |

| 10. Strip | HB400 | 40 mm |

to our digest

Our subscribers are the first to know:

Prize

Drawing

Perconal Data

Security

NO

SPAM

By leaving your personal data, you accept the Privacy Policy

Web programming b-m.ru

This site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies. Learn more.

I Accept