Price: call us or send an enquiry

Professional produces axles, pins, bushings according to its own drawings and technical specifications of the customer at its own production facilities. Theproduction is equipped with modern equipment thus making it possible for us to create products that comply with international standards.

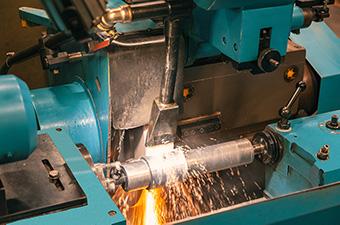

Axes, pins, and bushings are manufactured at Doosan high-precision Korean turning and milling machining centers, which allow for precision parts up to 0.005 mm.

This equipment allows performing a large number of operations in one installation of the part, that coupled with high workmanship of our staff, allows achieving the highest quality and speed of production of manufactured products.

Pins for construction excavators (operational weight up to 75 tons) are made of 40X steel.

Stages of processing are cutting, heat treatment (up to 240-280 HB), machining (grooving, trimming, drilling), hardening of high-frequency (50-55 HRS), grinding.

Pins for mining class excavators (operating weight over 75 tons) are made of 40XH steel (higher quality steel than 40X in chemical composition and physical and mechanical properties).

Stages of processing are cutting, thermal improvement (up to 260-300 HB), machining (grooving, trimming, drilling), hardening of high-frequency (55-60 HRS), grinding.

Excavator bushings are made of 20X steel.

Processing stages are cutting with dimensional allowances, cementation with soft tempering, shot blasting, machining, heat treatment (up to 300-350 HB), hardening (up to 62-63 HRS), external grinding.

to our digest

Our subscribers are the first to know:

Prize

Drawing

Perconal Data

Security

NO

SPAM

By leaving your personal data, you accept the Privacy Policy

Web programming b-m.ru

This site uses cookies. By continuing to browse the site, you are agreeing to our use of cookies. Learn more.

I Accept